From individual machines to green-field approach

Manufacture du Haut Rhin’s engineering competence span the entire process of small & medium caliber ammunition production, from tooling design, material behaviour, bullet and case manufacturing, through to final loading assembly and packing, with high quality control throughout ensuring compliance with international standards such as NATO.

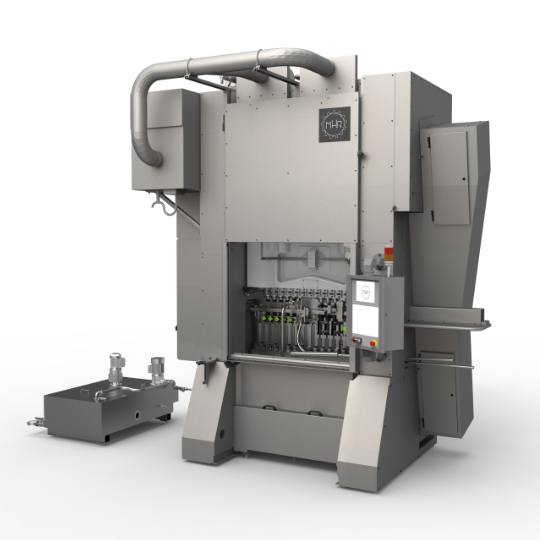

INDIVIDUAL MACHINES FOR ALL CYCLES OF AMMUNITION PRODUCTION

Manurhin machines provide a solution for every manufacturing phase:

- Cold deformation processes for cases and bullets including 2nd and 3rd draw.

- Intermediate thermal and surface treatment (degreasing, pickling and annealing).

- Turning machine providing extraction head turning, length trimming and mouth chamfering.

- Automatic high-rate accurate quality control of finished case and bullet.

- Sourcing, supply, and integration of primers.

- Case mouth and primer varnishing.

- Bullet and cartridges assembly.

- Automatic packaging and linking operations, greatly reducing manpower requirements.

Machines such as the PD250 (case press) and PB31/14 (bullet press) have become norms within the ammunition production market.

QUICK & EASY CONVERSIONS

Conversion process includes a complete evaluation of the machine and its components, enabling the customer to produce different calibers on the same machine, in a cost-effective manner.

COMPLETE LINES / GREEN-FIELD APPROACH

Installation of new lines or a green-field manufacturing approach are also within Manufacture du Haut Rhin’s capabilities: from the design of the factory’s infrastructure to the installation of new lines or the adaptation of existing ones.

For such turn-key long-term projects, a devoted team would accompany the client throughout all stages – and beyond!

References available upon request.